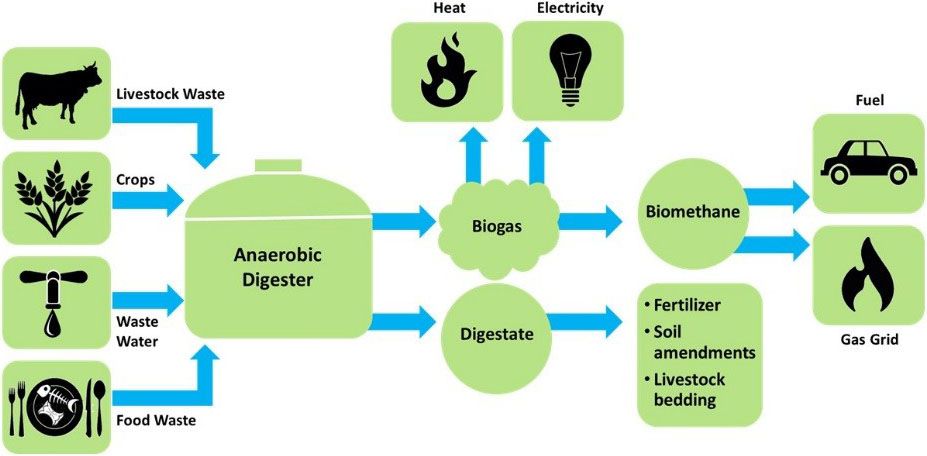

The AD process converts the specially grown crops, manure and slurries into methane and carbon dioxide gases in the proportion of approximately 60% methane (a potent greenhouse gas that is more than 25 times efficient as a greenhouse gas than CO2) and 35% carbon dioxide, and liquid digestate. The process requires an input of heat to provide a stable operating temperature of around 35°C to optimise the AD process.

The Biogas is ‘cleaned’ to separate off the CO2 which would be sold on to the food and drinks industry, which of course will be subsequently re-released into the atmosphere on consumption.

The methane is then ‘doped’ with propane gas from on-site storage to increase the calorific value to the equivalent of natural gas to be transported (according to Acorn at the Withersfield Public Consultation) to Milton Keynes, a round trip of around 130 miles. Additional gases such as hydrogen sulphide and ammonia may also be released from the digestate or feedstock storage dependent upon feedstocks employed. These last two gases are potential toxins to humans and wildlife.

What will be fed into the AD here? It’s not just waste – Acorn plan to use feedstocks (silage, ryegrass, maize and grass, as well as poultry litter ) – farmers will need to grow crops to feed this plant. Should land be taken out of food production, particularly at a time of constantly rising prices?

As a result of the large quantities of purpose-grown feedstocks required, and because the proposed site is not near land suitable for producing maize or rye, the feedstocks would have to be transported to the digester from a large area – this will mean more traffic from further afield.

The land near the proposed AD is heavy clay and not suitable for maize or rye, so the yield will be low – or the plant’s operators will go further afield for the crops required.

The Vesty Estate has stated they have no plans to grow maize, so the assertion that the grown feedstock would come from the applicant’s farm and surrounding farms is just not credible.

If the land needed was surrounding the digester, it would mean a circle with a radius of 5km around the AD for crop production. Given that much of the land surrounding the digester is not owned by the applicant, or is used for sheep grazing, we must assume that a much larger catchment area will be needed than the one implied in the application.

The proposed site would be very heavily road-transport-dependent, so any decarbonisation benefits will be reduced, if not eliminated, by the carbon burned transporting feedstocks and digestate.

In any case, whether the feedstocks fit into a crop rotation or not is not relevant – any land that would be turned to growing feedstock crops, is currently used for animal or human food crops. Isn’t this ridiculous when the UK is still a long way from being self-sufficient in food?

Productive land is a valuable resource, not to be taken out of use lightly; it is ideal for producing cereals, now in short supply due to the war in Ukraine.

Acorn have been equally vague about the delivery of the rest of the feedstocks – where exactly is that coming from? There are no large-scale pig or poultry units within 5 miles of the proposed site.

Summing up, Acorn has made only non-committal statements about local farms supplying feedstock, but this does not identify how much will be sourced locally and how much will come from further afield. The carbon cost of transport of either feedstock or digestate has not been identified.

All this land taken out of food production every year, transporting the feedstock over a large distance to the digester, the digestate back to farms, and then transporting the gas, by road, to Milton Keynes means that any benefit is tiny compared to the harm that this proposal would do.

- The proposed site would be very heavily road-transport-dependent, so any decarbonisation benefits will be reduced, if not eliminated, by the carbon burned transporting feedstocks and digestate.

- In addition, digestate, used repeatedly, carries damaging risks to land and environment – nitrogen pollution is one of the five most significant emerging issues on the environment (UN Environment 2019).

- The removal of food production for human and livestock consumption to support AD feedstock requirements is likely to damage local livestock operations and businesses who rely on those operations.

- This proposed operation is not an agricultural activity, but an industrial and commercial development more suited to a brownfield site, away from residential areas, and where infrastructure and communication networks are already developed.

“The use of food crops for biogas production will increase other environmental impacts, as well as causing competition with food production and related socio-economic consequences. Therefore, using agricultural crops for biogas production is not environmentally sustainable and should not be encouraged.”

– Whiting and Azapagic, 2014

Maize is a rapidly growing crop in the UK, increasingly being grown as an energy crop for AD to produce gas for fuel. Not only does this threaten food production – this same land could produce wheat or potatoes – but maize crops also have a negative impact on soils, leaving them exposed during much of the growing season which makes them vulnerable to erosion. It is harvested late when soils are often wet, so with heavy rain and heavy vehicles moving over the land, water runs off the surface of compacted and damaged fields, polluting waterways with pesticides and fertilisers and causing floods. Late harvested maize sites show high or severe levels of soil degradation. There is run-off and flooding from the proposed site on a regular basis – see this article from 2016: https://www.coventrytelegraph.net.

Alongside the criticism that cultivating energy crops is a waste of agricultural land that ought to be used to produce food, there is a worry that the UK could go the same way as Germany, where a boom in the biogas industry has changed the economics of agriculture. The demand for land to grow maize has resulted in a so-called ‘land-grab’ and has pushed up rents enormously.

According to the Soil Association, biogas produced from maize is not providing any net benefit to the environment. Research in 2014 concluded that

‘the use of food crops for biogas production will increase other environmental impacts, as well as causing competition with food production and related socio-economic consequences. Therefore, using agricultural crops for biogas production is not environmentally sustainable and should not be encouraged’. – Whiting and Azapagic, 2014, Life cycle environmental impacts of generating electricity and heat from biogas produced by anaerobic digestion, Energy 70, 181-193.

If we look at all the inputs and outputs: transportation, vehicle emissions, emissions from site construction, the large amount of power needed to heat the bio-digesters 24/7, the tiny contribution to national gas production – the AD process is far from ‘net carbon zero’.

Let’s look now at this Comparison of Renewable Energy Sources, from www.biofuelwatch.org.uk

On average, one hectare of a UK conifer plantation, when burnt as a biomass, will convert sunlight to 33.17 MWh (Megawatt hours) worth of energy annually

One hectare of solar panels in the UK will generate 481.8 MWH of electricity per year

Maize silage produces per hectare 12,350m3 of biogas, which in turn produces 296.4 MWh per year

Not only is the yield higher, but solar (and wind-power) are truly sustainable, 100% renewable, clean, and far more efficient than biofuels and biogas. Fossil fuel companies see biogas as a way to entrench their interests. They support biomethane as a substitute for electrification, so gas infrastructure can keep supplying fossil gas in the meantime. Biogas has received a lot of money through subsidies – these investments in fossil fuel infrastructure delay real progress.

Biomethane stands in the way of better alternatives, including dietary change, food waste reduction, planting woodlands, and renewable electricity.

If we look at all the inputs and outputs: transportation, vehicle emissions, emissions from site construction, the large amount of power needed to heat the bio-digesters 24/7, the tiny contribution to national gas production – the AD process is far from ‘net carbon zero’.